By Prof. S. Mangi Singh and Dr. Ayangbam Shyamkishor

Introduction:

The Lois are one of the two indigenous Scheduled Castes of Manipur, the other being Yaithibi. Literally the term Loi means subdued ones or those who pay tribute to a sovereign. There are numerous Loi villages in Manipur. However, not all the inhabitants are recognized as Loi villages. After Manipur’s merger into India, only inhabitants of eight Loi villages were given the status of Scheduled Castes. These villages are 1) Phayeng, 2) Sekmai (Awang Sekmai), 3) Koutruk, 4) Leimaram, 5) Leimaram Khunou, 6) Andro, 7) Khurkhul and 8) Kwatha. As a result, at present there are a number of other villages which have been recognized as historically Loi villages though their inhabitants are not recognized as Scheduled Castes. These villages are Khe-Sekmai, Thongjao, Thoubandong, Kakching, Sikhong, Ningel, Tensang, Chairel, Loibok Leishangkhong, Heiyel, Hangol, Phoubakchao, Waikhong, Thanga, Moirang, Wangoo, Nungoo, sugnu, Langathel, pallel and Arong Loi. At present, there are some organized demands from the inhabitants of these villages for their recognition as Scheduled Castes.

Awang Sekmai, a Loi village in the Imphal-Dimapur road (National Highway No. 39) is 19 km far from Imphal, the capital of Manipur. The traditional occupation of the people of this village, apart from agriculture, is that of the preparation of Alcoholic Rice Beverage. It is also an occupation mainly taken up by the womenfolk. In all, the people of Sekmai (as Awang Sekmai is popularly known) prepare three varieties of drinks manufactured from rice. They are “Pukyu”, “Waiyu” and “Leiyu”. “Yu” is the Manipur word for Alcoholic Rice Beverage and these three are three different varieties of Alcoholic Rice Beverage prepared from rice. The first two are basically meant for use during religious and ceremonial rites like that of the Lai Haraoba, and as such they are prepared only on rare occasions. They are not prepared fro general consumption or commercial purposes. The last one i.e. “Leiyu”, on the other hand is produced both for general use and commercial purposes. And even though all the three are different types of “yu” prepared from rice, it is “Leiyu” which have come to be popularly known as “yu”. Besides, of the three varieties, it is only the “Leiyu” or “yu” which is brewed by a process of distillation. Compared to this, the alcohol content of the other two varieties are low and they are mild drinks like beer. In fact, they may be more appropriately termed as rice beer. But as the term “yu” is used to mean both strong as well as mild drinks both are also taken as different varieties of “yu” or Alcoholic Rice Beverage. This paper explores the traditional skill of the Lois for preparing this Alcoholic Rice Beverage called “Leiyu”, henceforth termed simply as “yu” in the paper.

The process of distilling Alcoholic Rice Beverage or “yu”:

The process of distilling Alcoholic Rice Beverage is locally known as yu thongba. It normally takes four to five days depending on the weather. During summer (March to September), it usually takes four days and in winter (October to February), it usually takes five days. This is because of the fact that when the temperature rises during the summer months, the process of fermentation is faster and when the temperature falls during the winter months, the process is slower.

Two important ingredients are required for making yu. They are unpolished rice and hamei, a kind of malt. Unpolished rice is used for preparing yu because the people believe that yu prepared from it is much better in quality than yu prepared from polished rice. They believed that nutrients like vitamins, proteins, etc. are taken away if the rice is polished. This adversely affects the quality of the yu.

Hamei, on the other hand, is made up of rice and yangli, a wild creeper (Albizzia mycrophylla). Then the yangli is dried properly. Later, when the hamei is about to be prepared, it is cut into small pieces and are kept soaked for about two hours or so. Some unpolished rice is also left soaked in water for a night or for about 12 hours. Later, it is collected in a basket and dried for a while. The rice is then crushed so as to turn it into fine powder. The rice powder and the pieces of yangli are then mixed up together along with water. Then, the dough so prepared is turned into thick flat round shapes. These are called hameis. They are left to dry over flat and broad baskets. A lining of straw or paddy husks is made on the surface of the basket before they are spread without overlapping over one another. They are again covered by a cloth and allowed to dry for four or five days depending on the weather conditions. The lining of the surface of the baskets is believed to increase the warmth beneath the cloth. After drying it, the hameis are taken out and spread in the sunshine to make it further dry. Once it is done, the hamei is ready to be used for preparing the yu. It may be note here that a taboo is to be observed by the person who prepares the hamei. That is, while preparing the hamei, the person should not touch any kind of fruit. Otherwise, they believe that the whole preparation will get spoiled.

Utensils and other materials required for the distillation process:

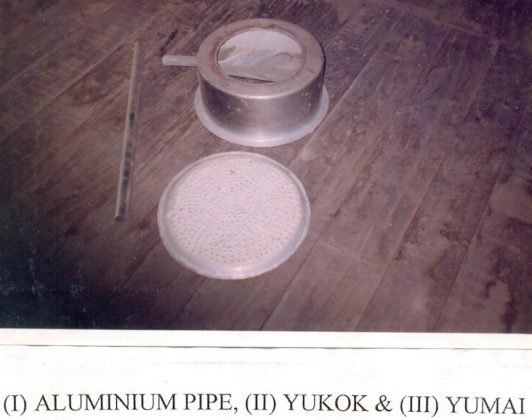

The different utensils and other materials required for the distillation are as follows: 1. Baskets made of bamboo; 2. Pots, earthen or aluminum ones; 3. Vessels; 4. Aluminum plates; 5. Aluminum tins; 6. Tubs; 7. Yukok, the container within which the steam shall get condensed; 8. Aluminum or rubber pipe through which the distillated yu will flow down; 9. Yumai, an aluminum plate with small numerous holes on which surface the steam is to be allowed to come up.

Steps towards distillation:

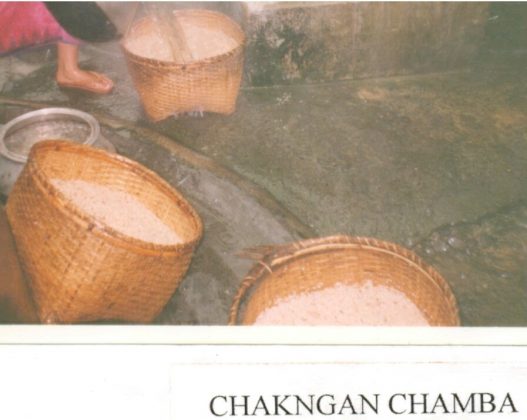

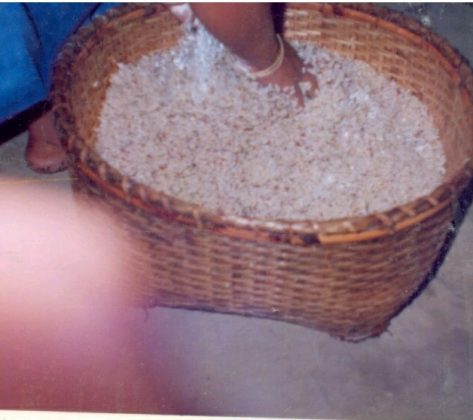

The process of distillation usually starts in the morning. First of all, the unpolished rice is cooked properly in a pot which is locally known as chakngan chaphu. The cooked rice is known as chakngan and the preparation of it is known as chakngan thongba. The cooked rice or chakngan is then taken out from the pot and kept in a basket locally known as chakngan sangbai (a big bamboo basket). After that the chakngan is washed properly by pouring water over the basket. This step is known as chakngan chamba. Proper washing of the chakngan (the cooked rice) is believed to serve many purposes. First, it allows the chakngan to cool down quickly and also helps in washing away the starch. Moreover, this also helps in quicker and proper fermentation of the chakngan. After washing the chakngan, it is allowed to drip dry for a while so that all the unsoaked water shall fall down. It may be remembered here that in olden days, people did not wash the chakngan. Instead, they spread it thin and wide on a big mat till the rice is cooled down properly. This method however is believed to be not so conducive to proper and quicker fermentation of the chakngan. So, this old method is more or less abandoned altogether nowadays by the people of Sekmai. Still, in some Loi villages in Manipur like Phayeng and Andro, this method is still continuing.

Next, the chakngan which is properly washed and dried up is mixed with the hamei. The hamei is first crushed into powder before mixing with the chakngan. The adding of hamei here serves twofold purposes – 1) to produce intoxication and 2) to accelerate the process of fermentation of the chakngan. As per a rough estimate, 30 gram of hamei powder is mixed with about chakngan prepared from 10 kg of unpolished rice. The mixture is then transferred into a basket (or a tin). A proper lining of leaves on the interior of the wall of basket is also made. The leaves normally used there is that of khangra tree (parrot tree, also known as Flame of the forest, Butea monosperma) or Hong-oo (Alocasia Indica) or Sangoi Hidak angouba mana (leaves of Datura mettel). The people have however, started using polythene sheets for lining the basket. It is mainly because of the fact nowadays it is becoming more and more difficult to find these leaves. Besides, polythene seeds are very handy to be used, easily washable and readily available in the market. The basket containing the mixture is then covered properly by warm clothes or sacks so as to make the mixture warm which in turn will help fermentation. The basket is then place above a tub. This process of keeping the mixture inside the basket is known as luthup chanba. An aluminum tin may also be used instead of the basket. The entire process is completed in the morning of the first day. On the 2nd day, the mixture, with fermentation having already started, will start realizing fluid. The fluid will drip out of the mixture drop by drop and get collected inside a tub. The so released fluid is known as khari. The dripping out of khari may start in the morning or later in the evening depending on the weather condition. During summer, the mixture gets properly fermented in the evening of the 2nd day. The fermented mixture is called khajee. The mixture before it gets properly fermented is known as khajee houdaba whereas the mixture when it gets properly fermented is known as khajee houba. During winter proper fermentation takes place in the morning of the third day.

It may be remembered here that the quantity of khari which is released during this period is less in the early stages of fermentation and is more at the final stages of fermentation. Proper fermentation of the mixture is also important for the quality of yu that will be distilled. If proper fermentation is not there, it will adversely affect the quality and quantity of the yu. However, proper fermentation of the mixture does not necessarily depend on the time allotted for the fermentation but mainly on the quality of hamei added to the mixture. Next, the properly fermented khajee will be transferred to another large container along with the khari which was released during the period of fermentation. Inside the large pot, they will get further mixed with water. The amount of water to be mixed up with the mixture of khari and khajee is roughly of the same proportion i.e., 1:1. This process is known as khajee khunba and this is done in the evening of the second day during summer and in the morning of the third day in winter.

The yuphu containing the mixture of khajee, kharee and water is covered properly by a yumai. This yumai is usually made of an aluminum plate with numerous holes all over the surface. Above it, a thin cloth is again placed. The purpose of the numerous holes in the plate is to ventilate the steam which will come up once the mixture is boiled. This yumai, along with the cloth also blocks solid particles from coming up. Above the yumai, the yukok is placed. The yukok is an apparatus, the bottom of which is hollow. Inside it, a tin sheet which surface is slightly curved and slanting upwards is inserted so that the distilled liquid may fall on it and also flow out over it. The upper surface of the yukok also has a large and circular opening. Over it, a pot which is full of cold water is kept. The entire process is completed in the evening of the third and fourth day during summer and winter respectively. The tin sheet is extended outside the yukok in the form of a hollow tube which is again connected to an aluminum or plastic pipe. And at the other end of the pipe, the yu-ya poon, a pot or plastic bucket for collecting the distilled yu, is placed.

Finally in the morning of the fourth or the fifth day as case might be, fire will be made beneath the yuphu to start the process of heating. In the beginning, heat is given as much as possible till the mixture inside the yuphu starts boiling. Once it starts boiling, the heat given is not only reduced but the level of the heat given is also uniformly maintained. The steam will start coming up to the yukok after passing through the yumai. Then, after coming into contact with the cold bottom of the pot with cold water above the yukok, it starts condensing. After a while, the condensed liquid will start dripping down drop by drop from the bottom of the pot on the slightly curved surface of the tin sheet. Then it will come out and, after passing through the aluminum or plastic pipe, gets collected inside the yu-ya poon drop by drop. The liquid so collected is the yu or Alcoholic Rice Beverage which is distilled. It must be noted that the water inside the pot on top of the yukok is changed every now and then with cold water so as to keep it cold all the time. The entire process of distillation continues for about five hours. After that it has to be closely monitored whether the process should be stopped or not. To examine it some of the Alcoholic Rice Beverage already collected is taken out. Then it is poured down into another container like a glass. If one notices bubbles coming up from the Alcoholic Rice Beverage inside the glass, the process is stopped. The Alcoholic Rice Beverage inside the yu-ya poon shall be removed and keep in a container. Now the process of distilling the Alcoholic Rice Beverage is over and the Alcoholic Rice Beverage is ready for consumption. The final step of taking out the distilled yu from the yu-ya poon is called yu kaiba.

Basing on its quality, the Alcoholic Rice Beverage produced by the people of Sekmai is classified into three classes viz. yu machin, yu aphaba and yu awouba. Yu machin is also simply known as machin. It is the best of the three and the percentage of alcohol is believed to be highest here. It is also very costly when compared to the price of the other two classes of Alcoholic Rice Beverage. Sometimes, its price is six or seven times higher than that of the others. This is mainly because of the fact that normally 12 to 15 liters of Alcoholic Rice Beverage is brewed from the Khajee prepared from 20 kg of rice. But if a person wants machin, then only the first two or three liters have to be collected and the process of distillation is stopped. Because unless collected with he first 2/3 liters, the rest of the distillate will be useless as Alcoholic Rice Beverage. Machin is also used sometimes as medicine. People apply it to get relief from pains in the body or body joints. Women also believe that applying it can remove pimples. Yu aphaba, the second type of Alcoholic Rice Beverage is also simply known as yu. Its quality is more than yu awaoba but less than that of machin. Yu awaoba, the third kind of Alcoholic Rice Beverage, is the Alcoholic Rice Beverage which is collected after the mixture is overcooked.

In addition to these three kinds of Alcoholic Rice Beverage, there are another two kinds of Alcoholic Rice Beverage. These two are mainly characterized by their distinctive smells. But they are also the products of the same distilling process. These two are yu ashinba or sour Alcoholic Rice Beverage and yu akaba or burnt up Alcoholic Rice Beverage. While the yu asinba smells sour, yu akaba smacks of a burning smell. If the quality of the hamei is bad, it adversely affects the fermentation process which in turn gives the Alcoholic Rice Beverage a sour taste. On the other hand, yu akaba is mainly the result of three things. Sometimes, proper fermentation of the khajee might not have taken place. In addition to that the amount of water added with the khajee and khari inside the yuphu may be less than the required proportion. When these two things happen, yu akaba is produced. It may also be the result of excess heat given to the yuphu. Because it leads to the burning up of the khajee inside the yuphu which in turn give the smell of burning to the Alcoholic Rice Beverage. It may also be mentioned here that yu akaba is also considered to be a good quality Alcoholic Rice Beverage. The only thing is that it has got an unwholesome smell.

Distillation of Alcoholic Rice Beverage and the economic life of the people:

In Manipur, there are other loi villages and tribal villages which distill Alcoholic Rice Beverage. But the quality of the Alcoholic Rice Beverage produced by the people of Sekmai is acknowledged as the best throughout the state. This is believed to be mainly because of the superior quality of rice which the people of Sekmai use for preparing the Alcoholic Rice Beverage. They never use cheaper or low quality rice for the purpose. Moreover, the proportion of Alcoholic Rice Beverage extracted by distillation is much less in Sekmai when compared to other places. This helps them in maintaining the high level quality of their product. For instance, here, they produce only about 12 to 15 liters of Alcoholic Rice Beverage from 20 kg of good quality rice. But in Phayeng and Andro, two other loi villages of Manipur, the people produced as much as 10 liters of Alcoholic Rice Beverage from 10 kg of rice. The quality of rice is also low there. As a result, the Alcoholic Rice Beverage manufactured in Sekmai is the most coveted one not only in Manipur but even in the neighboring states it is very popular and is known by the name Sekmai to distinguish it from the Alcoholic Rice Beverages produced in other places.

The age old occupation of Alcoholic Rice Beverage distillation among the people of Sekmai is a very lucrative one. In fact, along with agriculture, it is the main source of income for the people there. Almost every household of Sekmai produces it or is engaged in the Alcoholic Rice Beverage business in one way or the other. In short, the economy of the village largely centers round the production of it. For the individual family, it is not only a major source of family income but also an enterprise which helps them to take up other important and related income generating enterprises. For instance, most of the households in Sekmai are also engaged in piggery and it is very successful there. The leftover of the khajee after distillation or yupang as it is called, are very good for feeding the pigs. In fact it is popularly called ok-chak, meaning food for pigs. As the people engage themselves in Alcoholic Rice Beverage preparation throughout the year, there is no dearth of food for the pigs. As a result piggery is also an ever flourishing economic enterprise in the village. And the income so generated supplements the family income very well. This further brings another benefit to the people. The stools of the pigs are properly collected and used for producing bio-gas which is a great money saver. Many families in the village successfully use the bio-gas generated from pig stools for cooking and other purposes. Thus the Alcoholic Rice Beverage distillation is not only a major source of income for the people of Sekmai but it also supports other economic enterprises.

It may also be noted here that as the distillation takes place throughout the year, the people of Sekmai take due care that they have supply of rice throughout the year. Usually they use the paddy collected from their fields after leaving aside a certain portion of it for their own annual consumption. Still the paddy produced from their fields is not enough to last throughout the year. Therefore, many people, especially women from the neighboring villages will supply good quality rice to Sekmai thereby increasing economic activity of the village further. Even people from other districts of Manipur are engaged in supplying the rice to Sekmai.

About the writers: Prof. S. Mangi Singh, Political Science Dept., Manipur University, and Dr. Ayangbam Shyamkishor, Asst. Professor, Political Science Dept., Mizoram University

[1] Courtesy: Centre for Manipur Studies, Manipur University Seminar proceedings.

[ecwid widgets=”productbrowser search minicart” categories_per_row=”3″ grid=”10,3″ list=”60″ table=”60″ default_category_id=”21294227″ category_view=”table” search_view=”list” minicart_layout=”MiniAttachToProductBrowser”]